Quality and safety are the main requirements of NiMH hybrid battery packs. For developing and manufacturing NiMH hybrid battery packs, many factors must be considered from a quality assurance perspective to ensure basic requirements. Okacc has a very strict quality control system and environmental control systems. We have passed ISO9001: 2015 certification and ISO14001: 2015 in the past several years. Okacc guarantees a three-year limited warranty against quality and materials defects.

Okacc starts by purchasing high-quality raw materials and then assembling these materials on a production line using automated equipment, along with the latest in manufacturing processes and a high degree of precision quality control to ensure our battery quality. For instance, our NiMH hybrid battery processing, manufacturing, and inspection equipment are directly imported from professional equipment manufacturers in Taiwan. Other materials, like separators, are imported from qualified suppliers in Japan and China. We then use laser equipment to detect the thickness in the coating process. This laser equipment communicates with the coating machine in a feedback system to maintain tight tolerances and ensure that no cells are produced outside preset limits. Okacc also deployed a PDMS (Product Data management System) for quality control. Every step in the manufacturing process is checked, logged, and judged so that if a problem occurs, it will be discovered early, and any faulty product will be discarded. This automated attention to every step of the manufacturing process results in higher yields and, ultimately, lower production costs.

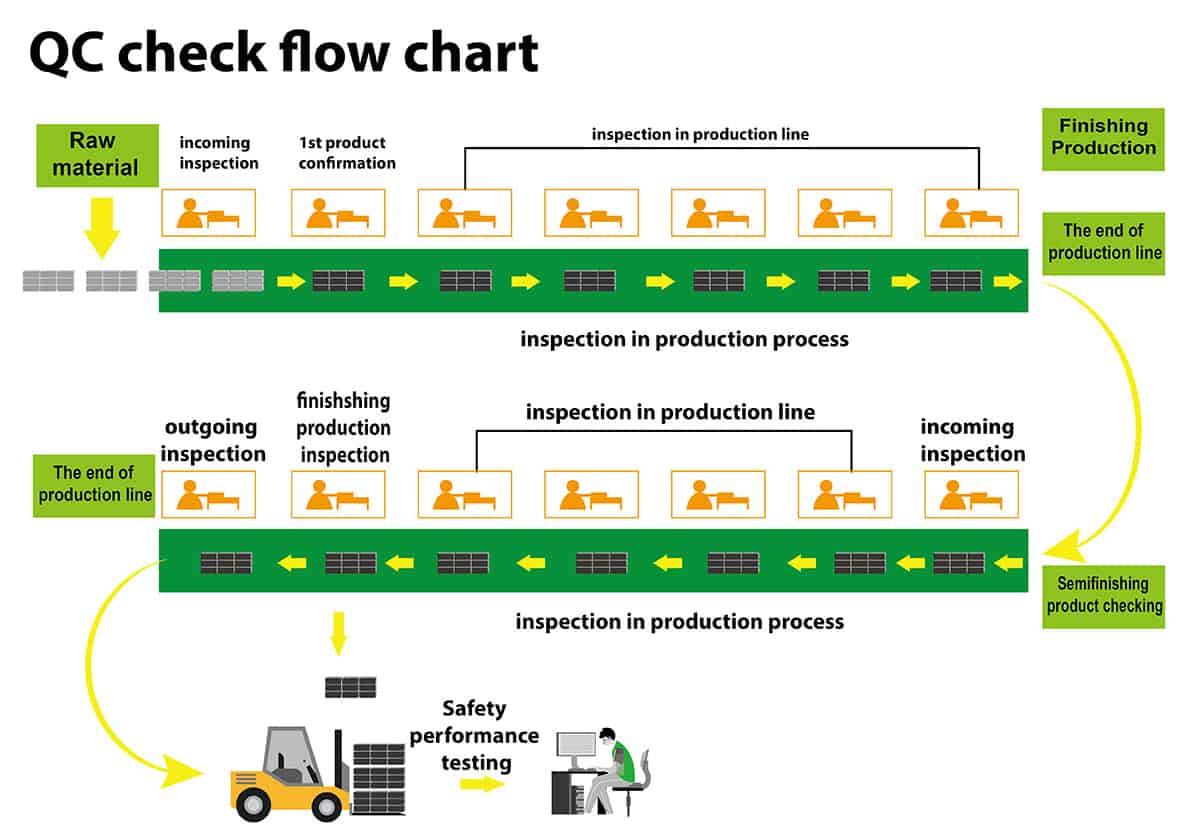

Okacc QC check flow chart

Okacc updated the operation equipment and working flow with a new water-based manufacturing method. With less labor cost and less equipment required, manufacturing has now become more effective. All advantages bring a higher qualified passing rate of products and excellent quality. Besides, the electrochemical performance is much better than before with water-based manufacturing. This talented technology became one of our core competitiveness of us.

The Battery separator is coated with a hydrophobic coating, and well-shaped surfaces offer a better environment for NiMH transformation. Metal doping also makes significant efforts for electronic conductivity. Thus, Our power NiMH battery, like some pouch cells, could deliver a sizeable continuous discharge current at an enhanced safety level. We could apply better thermal conductivity for pouch cells, so better battery performance and long cycle life would be improved.

Also, From slurry manufacturing to unit cell manufacturing with fully automated production equipment to ensure stability and consistency of battery quality. The water-based manufacturing, thermal conductive design, cell assembly, separators, and electrolyte aspects have been well organized, and the battery got superior safety. Okacc batteries have excellent thermal stability tests (and operation over a more comprehensive temperature range) and overall protection under stress conditions like over-charge, short-circuit, acupuncture, burning, etc. Okacc NiMH hybrid is the most reliable hybrid car battery available for customer application.

Developing, designing, testing, producing, and delivering a high-quality NiMH hybrid battery pack requires a commitment to and embracing quality assurance. By following the guidelines above, Okacc can move toward developing exceptional products that are also safe and environmentally friendly.

Okacc Hybrid Batteries

Okacc Hybrid Batteries